CASE STUDY

Orion’s MES

Transformation

Orion’s MES Transformation

From Paper-Based Processes to Review-by-Exception

with POMSnet Aquila

For over a century, Orion Corporation has been a cornerstone of pharmaceutical innovation and well-being in Finland and around the world. With over 70% of its sales coming from global markets, Orion recognized the need to modernize its manufacturing operations to remain competitive and continue delivering safe, effective products efficiently.

By 2016, it became clear that relying solely on paper-based production processes was no longer sustainable. Line-clearance, equipment cleaning, and batch documentation were all managed manually, with signatures collected by hand and reviews often delayed. The lack of digital systems made it difficult to standardize operations across departments, slowing down scale, compliance, and efficiency. Orion needed its first MES, one that could digitize production from the ground up.

Orion didn’t just need a software tool, it needed a digital foundation. A scalable, user-focused MES that could transform how work got done on the shop floor while supporting long-term growth and compliance.

Key challenges included:

- Paper-based workflows for critical steps like line-clearance, equipment cleaning, and batch documentation.

- High volumes of manual signatures and approvals, delaying batch release and increasing compliance workload.

- Lack of integration between systems, with no digital ink between production data, ERP, or equipment.

- Process variation across departments, making standardization and scaling difficult.

- No data-driven review capabilities, with no foundation for Review-by-Exception.

- Growing product complexity, requiring a system flexible enough to support diverse manufacturing needs.

Why POMSnet Aquila?

Orion chose POMSnet Aquila after a thorough evaluation of several MES vendors and for good reason. The platform offered a rare blend of flexibility, usability, and value that aligned closely with Orion’s goals and operational realities.

This strong combination of adaptability and innovation made POMSnet Aquila the ideal foundation for Orion’s MES transformation.

Key reasons for choosing Aquila included

- Configurable without compromise: Aquila accommodated Orion’s existing processes and mixed product portfolio without forcing unnecessary workflow changes.

- Strong value for investment: Compared to other MES options, POMSnet Aquila delivered robust functionality and scalability at a competitive cost.

- Simplified licensing: The licensing model eliminated the need to manage user counts, making the system easier to scale.

- Modern design and UX: The interface was clean, modern, and intuitive - making a strong first impression and requiring minimal training.

- Operator-friendly: Younger team members could learn the system quickly on their own, accelerating adoption across sites.

- Support for complex recipes: The system handled specialized recipes and variable production workflows with ease.

- An evolving platform: POMS regularly introduces new feature and updates, giving Orion confidence in the system’s long-term roadmap.

The Solution

POMSnet Aquila Implementation in Action

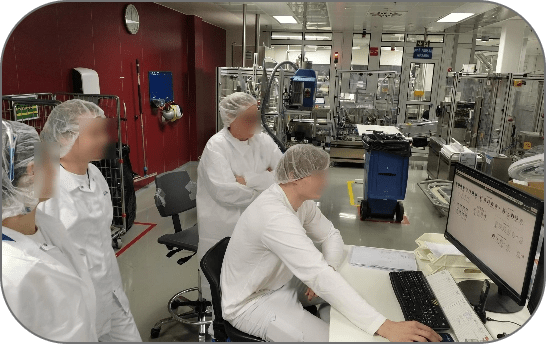

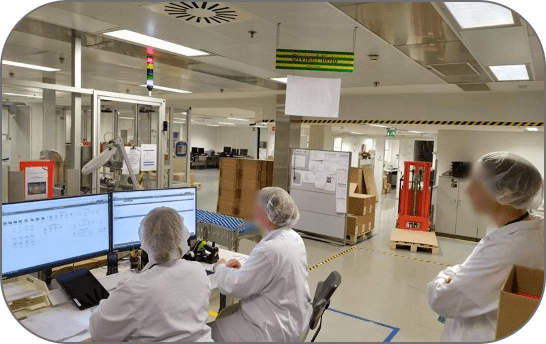

With the decision made, Orion got to work. Rather than take a “lift and shift” approach, Orion’s MES team embedded themselves on the shop floor, collaborating with operators to deeply understand current workflows and design digital processes that truly worked in practice - not just on paper.

After a successful proof of concept in 2020, Orion began building core functions in Aquila. By 2022, weighing and dispensing modules were rolled out to all manufacturing sites. The company then launched its first full MES pilot in the anticancer manufacturing and packaging department, going live in October 2023. This pilot encompassed everything from equipment picking and line-clearance to assembly, manufacturing, cleaning, and packaging.

To validate each rollout, Orion introduced a novel “placebo batch” testing method - allowing teams to run realistic production simulations before go-live. This not only helped fine-tune workflows but served as a powerful training tool for operators.

The Results

The results of the pilot were clear and transformative:

- Paperless Production: Manual line-clearance, cleaning, and assembly forms were replaced with fully digital workflows.

- Operator Adoption: POMSnet Aquila was quickly embraced thanks to its intuitive design - validated by research from the Turku University of Applied Sciences.

- Faster Batch Reviews: The system reduced the volume of manual batch record checks, speeding up time to release.

- Review-by-Exception in Sight: Orion began building an Automation Integration Layer (AIL) to connect equipment data directly to POMSnet, creating a real-time data pipeline to support Review-by-Exception at scale.

- Scalable and future-ready: The success of the anticancer department pilot led Orion to commit to full MES deployment across all manufacturing and packaging departments by 2028.

Looking Ahead

With over 400 pieces of equipment across Orion’s operations, approximately 100 have been identified as critical for integration into the MES system. The goal is to build a future where the majority of deviations are flagged automatically, enabling staff to focus only on what truly needs attention - a significant leap toward operational excellence.

To support this journey, Orion has established a MES Center of Excellence, tasked with maintaining and continuously evolving the POMSnet platform as the digital backbone of Orion’s production.

Orion’s journey with POMSnet Aquila is more than a system upgrade - it’s a true cultural shift toward smarter, streamlined, and more scalable manufacturing. Through bold vision, collaborative execution, and a strong technology partner in POMS, Orion is shaping the future of pharmaceutical production.

Let’s Talk

TOLL FREE:

855-436-POMS (7667)

INFORMATION:

info@poms.com

SALES:

404-386-9279

sales@poms.com

Contact us to learn how POMS delivers the industry’s most flexible solution, find support, or schedule a demo today